Process Engineering

Bring Expertise & Experience to Your Chemical & Process Engineering Services

Unit Optimization Studies

Operations Troubleshooting

Detailed Equipment Sizing

Distillation Design and Optimization

Firewall System Design

Flare System Design

Control Valve and Meters

Relief Valve Analysis, Documentation, and Mitigation

HAZOPs

Risk Assessments

Facility Siting Studies

Dust Containment Studies

Safety Instrumented System (SIS) Design

Flare/Blowdown Systems

Featured

Process

Projects

Eagle Ford EOR Pilot Project

Keystone provided front end engineering design (FEED) and detailed engineering design for a 30 MMSCFD Enhanced Oil Recovery Pilot in the Eagle Ford black oil area. The pilot area consists of two adjacent pads, with 21 injection wells separated by six buffer wells to monitor pressure and communication. The project scope included extending the well pad to accommodate gas injection and processing trains. The new processing train compresses, sweetens, and dehydrates gas utilized for fuel gas and flare purge with the remaining volume entering a header common with the injection compressor suction and gas lift pipeline.

Centralized Storage

To support facilities associated with the Centralized Storage, Keystone provided project management, engineering, and design FEED services. The scope included the installation of temporary storage and stabilization capabilities for the Eagle Ford Region to act as a surge for the Condensate Trunkline. Additionally, the project involved future expansion capabilities for an additional storage tank and vapor recovery to gather the flash gas. The stabilization capabilities were necessary to get RVP to an acceptable level for sales contract. The design criteria associated with the scope included a design storage capacity of 30,000 BBL and a design facility average flowrate of 120,000 BOPD.

Underground Storage Expansion

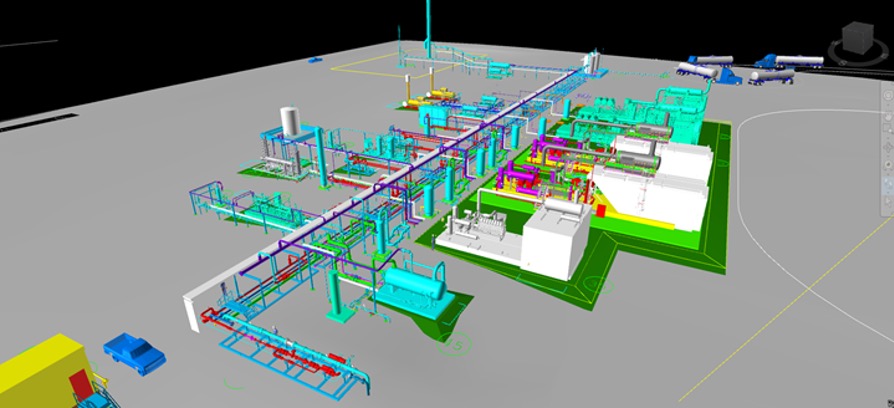

As a significant effort to support a new Ethane Cracker, Keystone performed project management, engineering, and design for the $165MM expansion of an underground storage terminal in Sulphur, LA. The project's scope included installing a new brine pond, four ethylene transport pumps, ethylene dehydration system, CO2 Scrubber, flare system, and piping to the new wells at the underground storage facility. Additionally, Keystone executed the design of the associated meter stations and horizontal directional drill packages for the new Ethane & Ethylene pipelines.

New Alkylation Unit

Keystone provided multi-discipline engineering and design services for a major project to install a $125MM new Alkylation Unit. The design basis of the new Alkylation Unit involved utilizing an existing decommissioned unit at another site. Nine pieces of equipment at that site were refurbished and reused for this project, including a refrigerant compressor, contactors, and six pressure vessels. One reboiler/heater, three towers, ten tanks, 11 heat exchangers, 21 drums, and 49 pumps were specified, purchased new, and installed. The additional connected electrical load required an expansion of the existing electrical substation including 800 new instruments.

Additionally, the project required new cooling towers and instrument air compressors since the existing facilities did not have adequate capacity. An existing LPG Truck Loading Rack required relocation and demolition to provide adequate spacing for the new unit.

Sour Water Stripper Unit

To support an increase in the Sour Water System's capacity, Keystone provided project management, engineering, and design services for the FEL 3 and detailed design phases of the project. The new system design included a capacity of 120 GPM sour water charge and 40 GPM turndown case.

The scope of work for the new Sour Water System Unit included sour water feed pumps, sour water feed/product exchangers, stripper tower, pump around pumps, overhead cooler, sour water reboiler, tempered water pumps, and a sump pump. Additionally, the new unit tied into steam, instrument air, and power systems.

Sulfatreat Phase 3 Engineering & Procurement

Keystone provided engineering, design, and construction support for a significant process upgrade at the refinery. The multi-discipline project added new SulfaTreat technology designed to remove Hydrogen Sulfide (H2S) from the continuous flare system. A highly accelerated schedule was vital to meet newly issued federal regulations from the Environmental Protection Agency (EPA). The arduous 15-week project schedule showcased one of Keystone’s greatest strengths– the ability to be responsive and rapidly assemble an elite project team.

Keystone provided procurement support in addition to civil/structural, process/mechanical, electrical, instrumentation, and controls/automation engineering. The highly experienced team was able to engineer innovative solutions to save time and keep the project on schedule. The owner and the construction contractor commended Keystone for producing all deliverables on-time or early and doing so with a remarkably high level of quality.